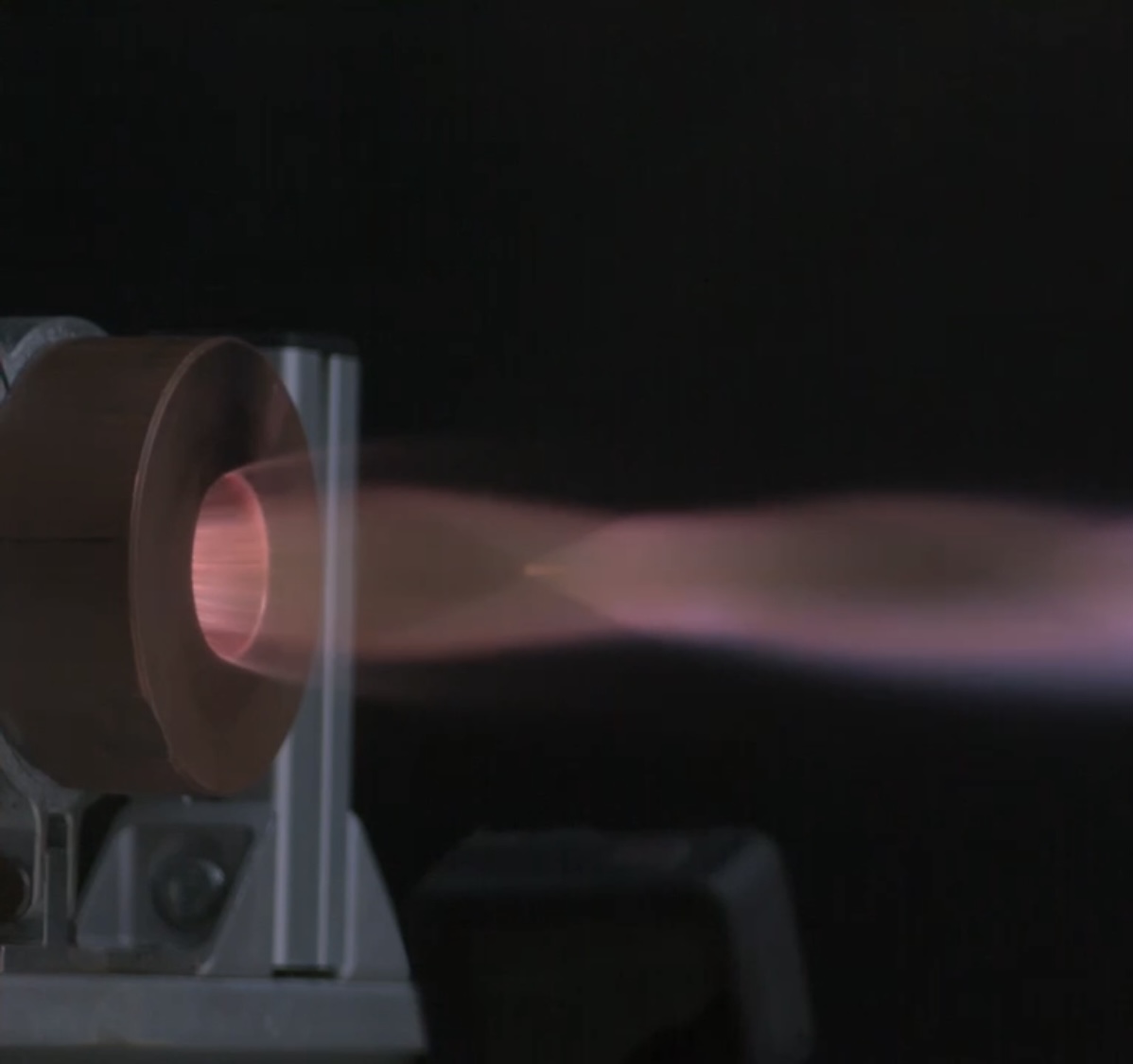

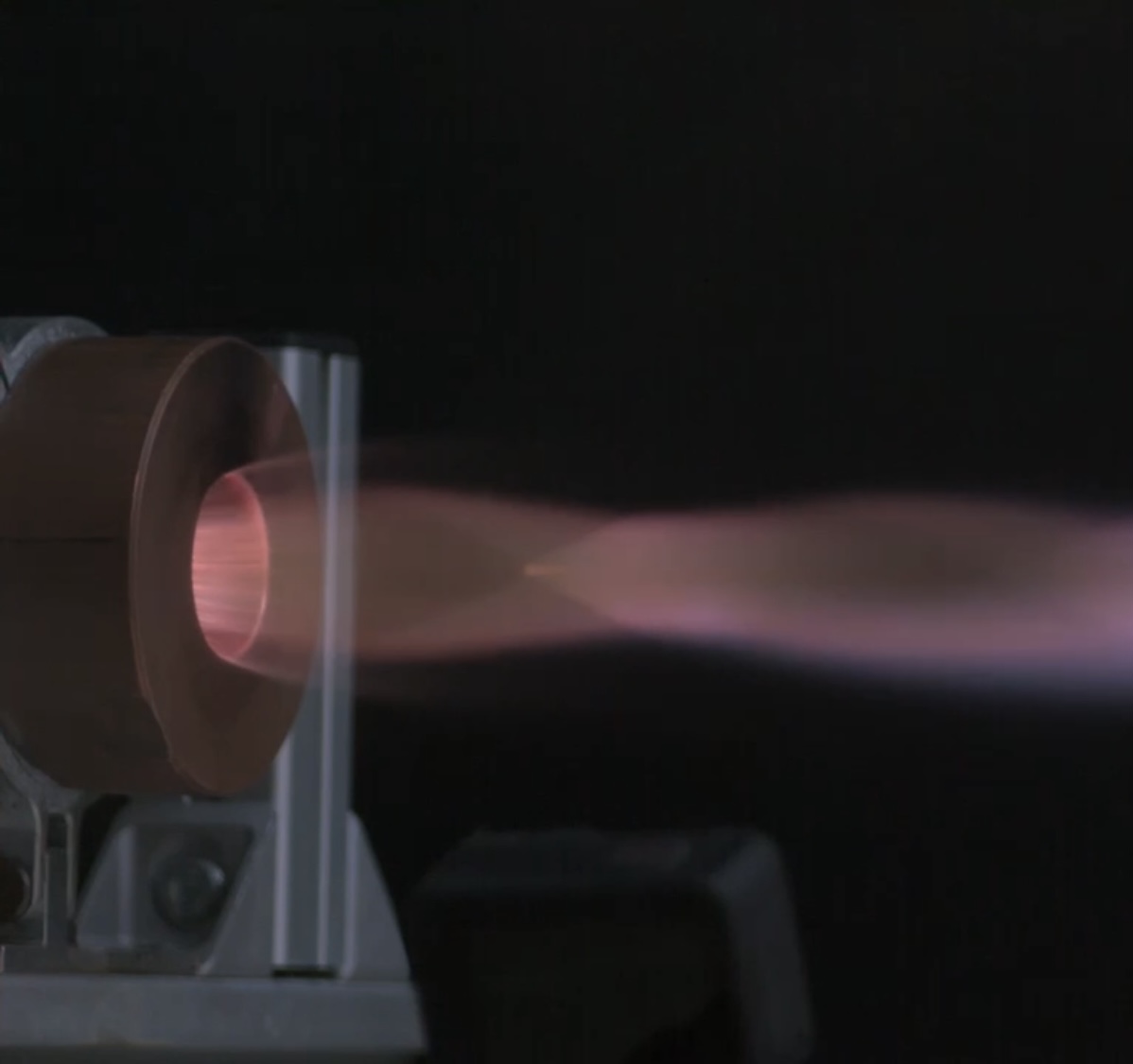

F-100 is our rocket hopper bi-propellant engine. This engine uses N2O and IPA for a maximal thrust of 1.2kN and a minimal thrust under 0.5kN.

The main engine parts are made using the metal additive manufacturing technology (SLM) with inconel 718.

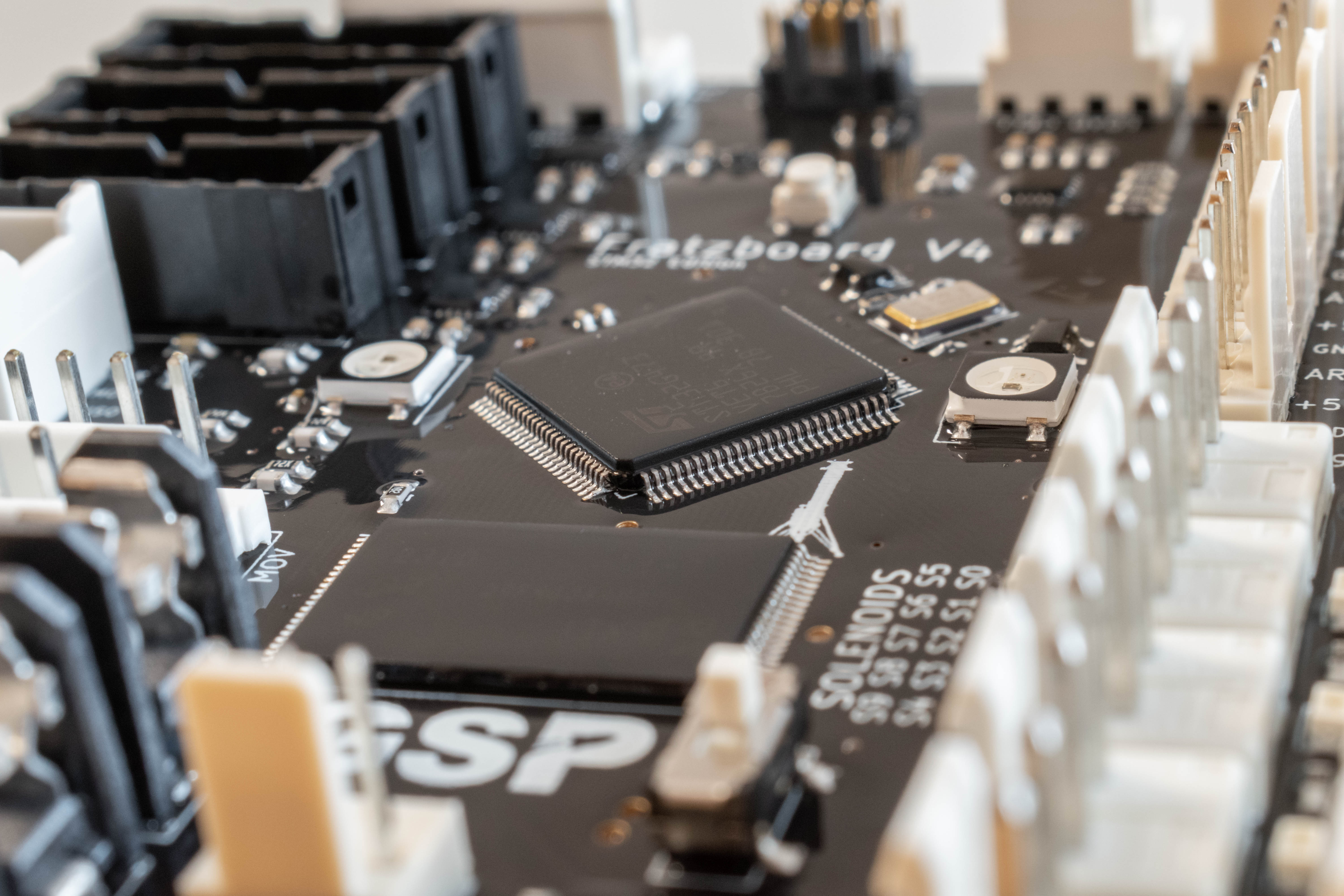

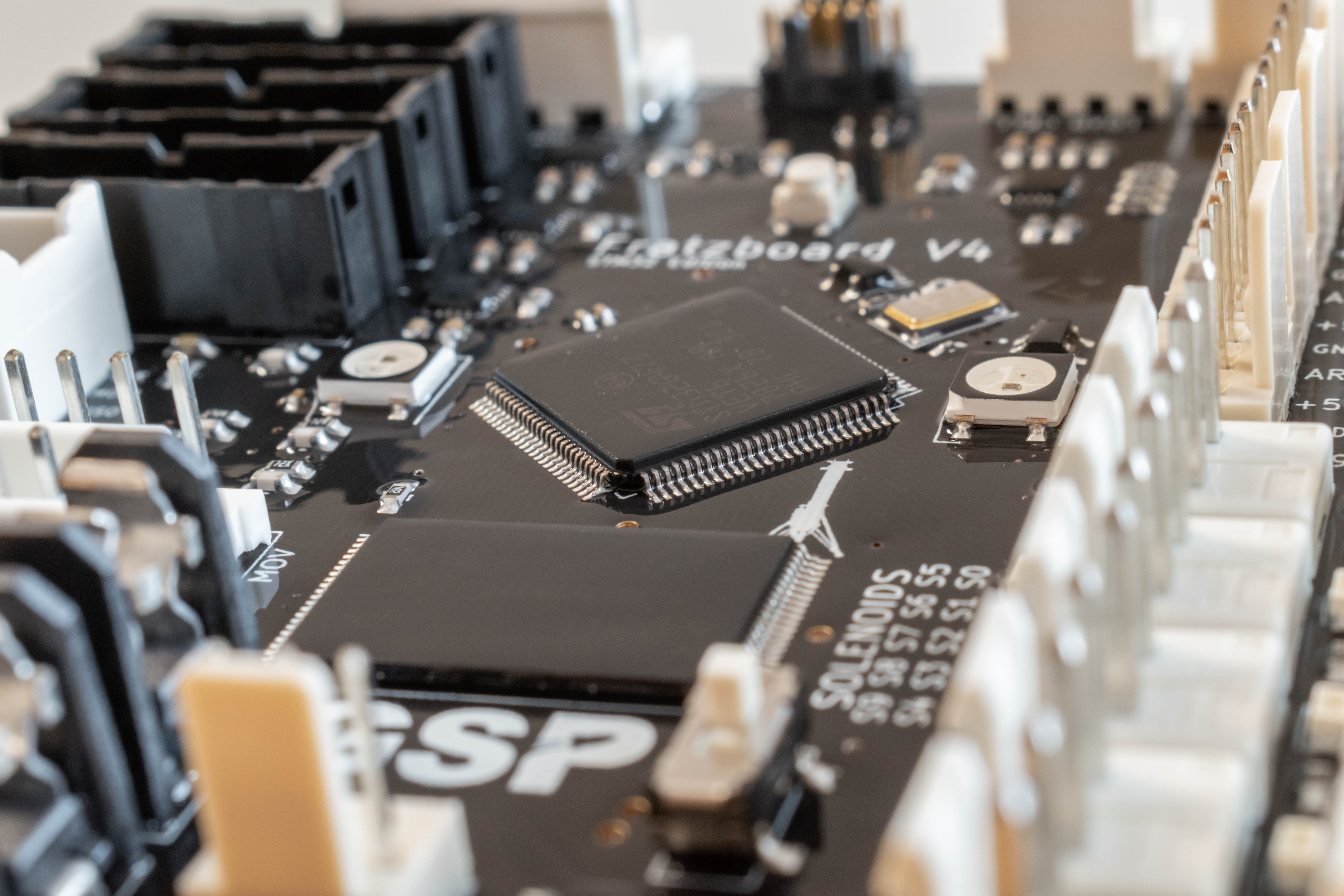

The motor ignition sequence is automated by a custom made printed circuit board designed by our team. It can also communicate with our control station to send or receive commands.

To guarantee safe operations, we built a test infrastructure tailored to our needs. We also rely on safety experts to help us make safety a priority.

We successfully fired our engine in May 2022. This is a first for swiss students. We are currently doing more test to gather as much data as possible.

F-100 has already undergone numerous improvements: main valves that are now responsive enough for thrust regulation, a liquid torch igniter, an actively cooled combustion chamber, and many other components have been redesigned for Colibri flights. We will soon begin integrated ignition tests with Colibri!

The main engine parts are made using the metal additive manufacturing technology (SLM) with inconel 718.

The motor ignition sequence is automated by a custom made printed circuit board designed by our team. It can also communicate with our control station to send or receive commands.

To guarantee safe operations, we built a test infrastructure tailored to our needs. We also rely on safety experts to help us make safety a priority.

We successfully fired our engine in May 2022. This is a first for swiss students. We are currently doing more test to gather as much data as possible.

F-100 has already undergone numerous improvements: main valves that are now responsive enough for thrust regulation, a liquid torch igniter, an actively cooled combustion chamber, and many other components have been redesigned for Colibri flights. We will soon begin integrated ignition tests with Colibri!